Smart Factory Implementation

Industrial AI and IoT for predictive maintenance

Company Profile

A leading international automotive parts manufacturer with 20+ plants.

Industry

Manufacturing

Region

Europe & Asia

About the Client

Machine Runtime Increase

Maintenance Cost Reduction

Full Scale Deployment

Challenge

The primary challenge was the 'black box' nature of their older production lines. Maintenance teams relied on schedule-based or reactive repairs, meaning parts were often replaced too early or, worse, after they had already failed. There was no real-time visibility into the health of critical CNC machines and robotic arms.

Furthermore, the environmental data from the factory floor—temperature, vibration, and humidity—was not being correlated with machine performance, leading to 'invisible' causes of degradation that manual inspections could not detect.

- Unpredictable equipment downtime causing production delays.

- Inability to monitor machine health in real-time across global sites.

- High cost of emergency repairs and rush-shipped spare parts.

- Lack of integration between OT (Operational Tech) and IT (Information Tech).

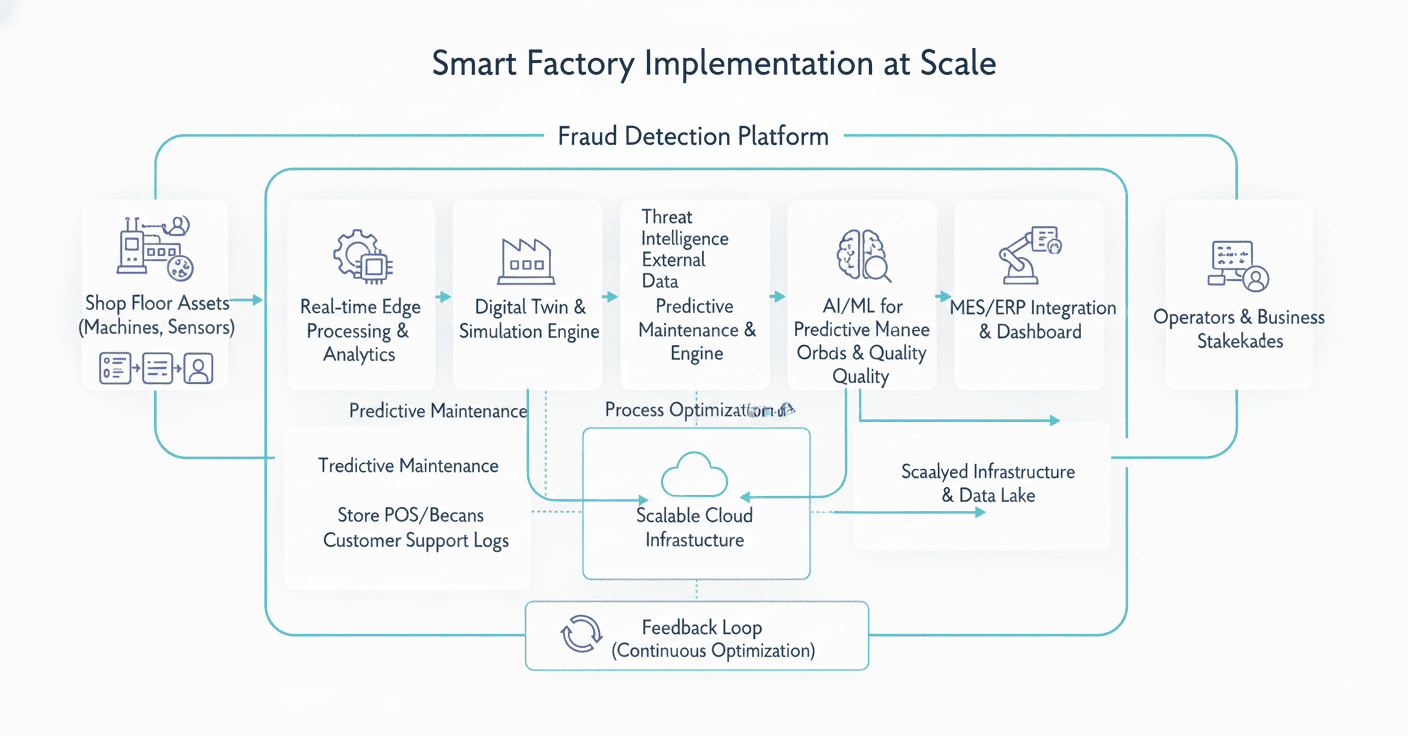

The Solution

Predictive Maintenance Engine

The Outcome

Industrial ROI at Scale

Reduction in Downtime

OPEX Savings

IoT Connectivity

"WebbyButter didn't just give us data; they gave us foresight. We've moved from putting out fires to preventing them entirely."

Continue Exploring

More Success Stories

Discover how we've helped leading global enterprises transform their operations through custom-engineered AI solutions.

Personalized Learning Platform

Adaptive learning system for enterprise education

Content Recommendation Engine

High-performance hybrid streaming recommendation engine

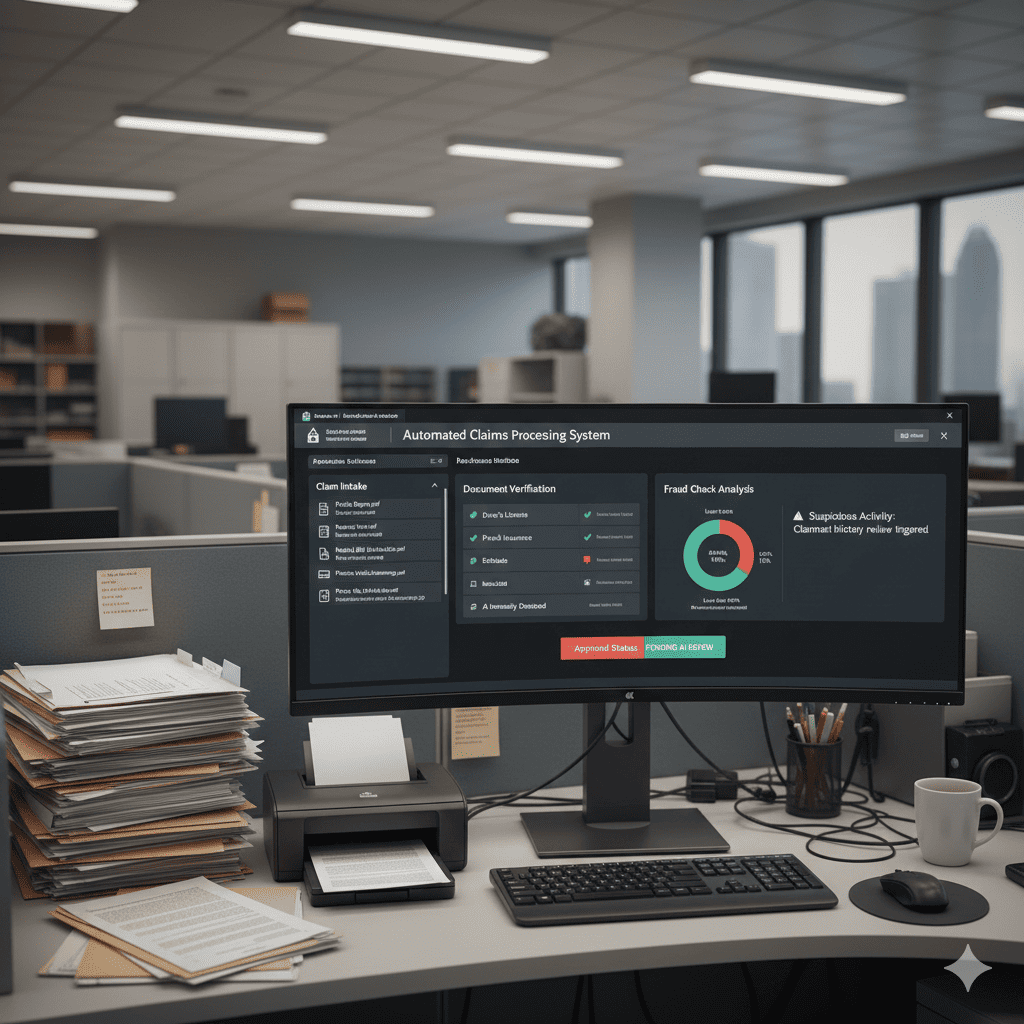

Automated Claims Processing

GenAI for rapid insurance claim extraction and validation

Stay ahead of the curve

Receive updates on the state of Applied Artificial Intelligence.

Ready to see real ROI from AI?

Schedule a technical discovery call with our AI specialists. We'll assess your data infrastructure and identify high-impact opportunities.